HJT Leadership Initiative: 760W+ Club Ushers in a New Era

On March 6, the 10th Roundtable Meeting of the High-Efficiency Heterojunction (HJT) 760W+ Club and the launch event for the HJT Frontier Accelerator took place in Xuancheng, Anhui, known as the “HJT Capital.” As the first closed meeting of 2025, the event was held under the theme “HJT Innovation Redefines Benchmarks, Powering an Industry Transformation.” Hosted by Huasun, attendees included CNBM Jetion Solar, Golden Solar, Grand Sunergy Technology, Jiangsu Soltrend, Leascend Photovoltaic, Mingyang, Quanwei, Shanghai Hency Solar Technology, SoleFiori, SPIC New Energy, Tongwei, and Zhejiang Winhitech (listed alphabetically). The discussions focused on technological breakthroughs, market collaboration, and policy opportunities. During the event, the "740W+ Club" was officially upgraded to the "760W+ Club," marking a new phase in HJT technology development.

01 Technology Ark: Patent Autonomy Safeguards Energy Security

Xu Xiaohua, chairman and CEO of Huasun, delivered the keynote speech. “National ministries are actively driving the energy transition, and future competition among nations will center on advanced photovoltaic (PV) technology,” Xu said. “Despite its technical advantages, HJT technology has yet to achieve widespread market adoption. However, domestic and foreign policy incentives, along with overseas project opportunities, have created a window for expansion.” Xu emphasized that HJT serves as a strategic pillar of new productive forces, empowering China’s PV industry to update its technology and surpass global competitors. He highlighted HJT’s freedom from patent risks, positioning it as a key technology for overcoming international technological barriers and ensuring energy security. “As the global PV industry becomes entangled in patent disputes, HJT’s 100% independently developed and controllable technology path shields Chinese companies from infringement risks. This makes it the ‘Technology Ark’ of national energy security,” he said.

Liu Chang, executive secretary-general of the High-Efficiency HJT 760W+ Club and founder of SOLARZOOM, reviewed the club’s achievements and challenges since its launch in 2024. “Over the past year, significant progress has been made in technology promotion and market expansion. State-owned enterprises have issued tenders for approximately 15 GW of HJT products, reflecting growing market recognition. However, more collaboration is needed in industrial synergy, technical standardization, joint procurement, and financing support. Looking ahead to 2025, the club plans to enhance resource-sharing mechanisms, strengthen industry cooperation, and encourage active participation from its members,” Liu said.

Wang Xin, chairman of Leascend Photovoltaic, noted, “HJT technology has progressed from a 1GW exploratory phase to nearly 15GW in annual shipments. This success stems from the industry’s unwavering commitment to innovation.” Wang suggested the club reinforce coordination, deepen collaboration, uphold the rotating conference system, and drive substantive breakthroughs with a solution-oriented approach.

02 HJT Leadership Initiative Launched: Full-Process Advancement Unlocks 760W+

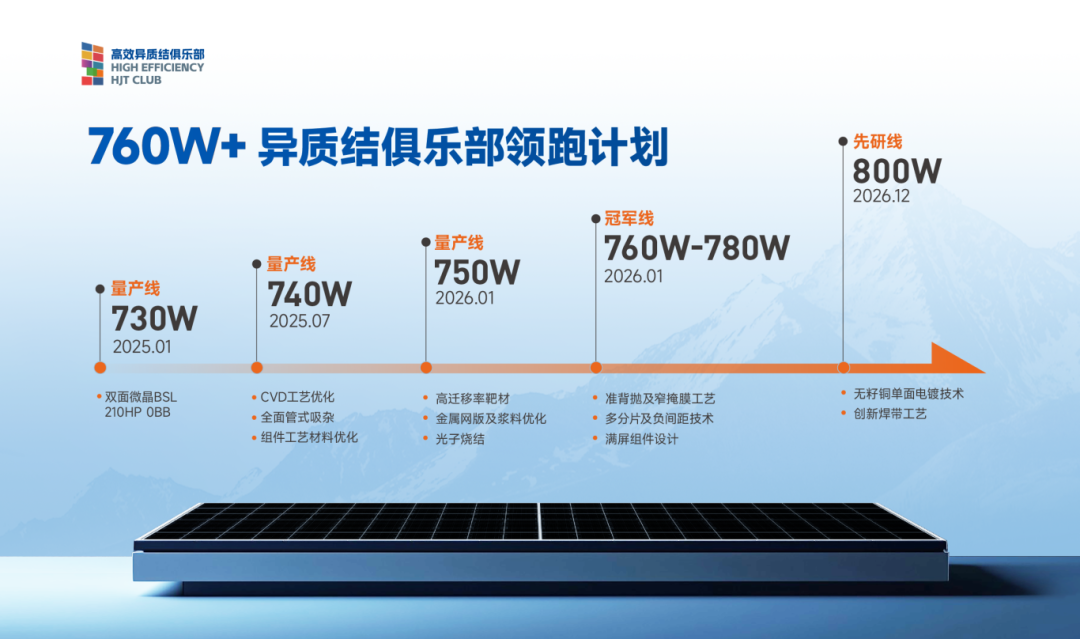

Huasun officially released the "760W+ Mass Production Implementation Strategy and Technology Roadmap" at the conference, unveiling a three-phase strategy for advancing HJT technology for the first time.

Phase One: Process Optimization to Build a Solid Foundation

The industry has already achieved mass production of 730W modules using the standard bifacial microcrystalline HJT process for 210mm products, with an efficiency of 23.5%. Based on the existing hardware configuration, the production line has optimized the chemical vapor deposition (CVD) process, enhanced module materials and manufacturing, and upgraded gettering techniques. Mass production of 740W with efficiency increasing to 23.8% is expected by June 2025.

Phase Two: Innovation-Driven Breakthroughs

By introducing high-mobility target materials and photon sintering, the technology refined metal screen printing and paste compatibility and implemented secondary light conversion encapsulation films. By the end of 2025, mass production lines with existing hardware configurations are expected to produce modules reaching 750W, with efficiency exceeding 24%.

How to break the 24.5% efficiency barrier while achieving BC-level performance? The solution must sustain HJT products’ ultra-high bifaciality and enhance their power generation strengths. The club’s research and development (R&D) team has innovated upon the traditional back-polishing process with low bifaciality, using the new quasi-back-polishing process to boost backside light reflection and absorption. The bifaciality loss is now controlled below 1%. Both CVD and physical vapor deposition (PVD) introduce ultra-narrow mask techniques and carrier plates, using selective edge-etching to minimize rework from overcoating. These process innovations increase the effective power generation area, improve light absorption management, and raise cell efficiency by over 0.5%. The module power will jump to 765W with a conversion efficiency of 24.6%. The hardware upgrades require minimal investment and can be implemented across the club members’ champion production lines.

Beyond cell-level advancements, module technology is also evolving. The upgraded design integrates multi-segment with zero-busbar (0BB) architecture, enhanced by negative spacing technology and borderless panel optimization. While retaining the standard 1303×2384mm module dimensions, the module power can be increased by 15W. The total upgrade cost for each gigawatt of cell and module production lines is expected to stay below 20 million RMB. By early 2026, champion production lines undergoing combined cell and module upgrades will produce 780W HJT modules, achieving 25% efficiency while maintaining bifaciality above 85%—all with clear and streamlined production processes and manageable hardware investment.

Even with all these process innovations, new HJT production lines remain more cost-effective than BC lines to achieve over 25% efficiency. They offer comparable or superior front-side efficiency to BC technology. Cell yield rates will stay above 99%, module yields above 99.5%, and most importantly, bifaciality will remain at a baseline of 85%, allowing application in ultra-high bifacial (>95%) vertical module designs. This efficiency improvement without sacrificing bifaciality further strengthens HJT’s power generation advantages.

Phase Three: Extreme Breakthroughs Targeting 800W

Beyond 780W, how can HJT push the limits even further? Insights from early research lines within Club point to seedless copper electroplating—either single-sided or bifacial—as the next breakthrough. Initial research on seedless copper electroplating shows promising results:

- Single-sided electroplating significantly improves front-side efficiency while enhancing contact resistance between the indium tin oxide (ITO) film and welding ribbon. This translates the cell efficiency gains directly into higher module power output, with an effective increase of 0.5%.

- New welding ribbon designs in module assembly can dramatically reduce light reflection, with initial tests indicating a 10W power gain.

The combined effect of these advancements is projected to boost module power by over 20W, pushing front-side HJT module power to 800W at 25.75% conversion efficiency. This milestone would represent the highest power and efficiency ever achieved on a standard-sized crystalline silicon module. Even at this level, bifaciality remains above 85%, ensuring that HJT remains the ultimate crystalline silicon technology before perovskite-HJT tandem modules enter the market.

“This isn’t just a power race—it’s about redefining China’s PV industry’s ability to push manufacturing limits,” said Xu. “Every watt of improvement comes from our partners’ relentless pursuit of technological breakthroughs. It’s about achieving the highest conversion efficiency and maximum total energy output with the simplest process, the least materials, and the lowest energy consumption.”

Club members unanimously endorsed the roadmap, recognizing its role in establishing a clear “process-material-equipment” technological evolution framework and a lifecycle-based levelized cost of electricity (LCOE) evaluation system.

Wang Wenjing, chief scientist at Huasun, emphasized the importance of laser processing techniques and quasi-back-polishing methods. Enhancing efficiency, reducing costs, and improving reliability are the core directions of the HJT technology breakthrough. He noted that bifacial microcrystalline structures still have untapped efficiency potential, providing the foundation for 760W+ module scalability.

Zhou Jian, chairman of Maxwell, stated that the company is optimizing HJT cell production equipment, refining CVD edge optimization, PVD ultra-narrow masking, and selective edge-etching. Ultra-low silver content silver-coated copper paste (Ag content <15 wt%) is developed to boost efficiency while lowering production costs. On the module side, innovative welding ribbon technologies could add another 10W, further enhancing HJT’s cost-effectiveness and efficiency.

03 Application Breakthrough: Scenario-Driven Deployment Reshapes Competitiveness

Scenario-driven innovation has emerged as a key strategy for breaking market barriers. Qiu Wenkai, General Manager of Mingyang, presented the report “HJT PV Module Vertical Installation System and Steady-State Power Supply System.” Qiu highlighted that HJT vertical installation systems, leveraging a dual-peak power generation curve, achieve stable output. Combined with high bifaciality and time-of-use electricity pricing strategies, these systems significantly enhance revenue generation. Even without energy storage, they can effectively manage peak shaving and valley filling. With minimal storage, they can support high-stability applications such as data centers and hydrogen production.

Jiang Fangdan, Director of the PV Research Institute at Tongwei, emphasized the importance of exploring new solutions beyond silver-coated copper to further reduce costs and improve efficiency. “2025 will be the critical year for market and field validation of various technological solutions,” Jiang noted. “Only technologies that withstand real-world application testing can secure a lasting competitive edge in the future PV market.”

04 Ecological Collaboration: From Standardization to Value Transformation

As China’s PV industry enters a fully market-driven phase, an invited expert from Anhui Province shared insights from the report “Accelerating Green and Low-Carbon Transition in Anhui Province: A Study and Insights on Recent Key New Energy Policies.” While interpreting policy trends, the expert stated, “The core of electricity market reform in the renewable sector is to foster rational competition. The industry must shift from extensive ‘scale expansion’ to refined ‘quality competition.’ HJT enterprises must develop high-frequency response capabilities to navigate renewable energy market volatility, establishing market moats through differentiated technological advantages.”

Gao Fei, CEO of Grand Sunergy Technology, remarked, “The 760W+ module power target is exhilarating, but the critical path lies in making steady progress in a planned, annual, and phased manner.” He emphasized that amid China’s evolving national unified energy market, club members must strengthen collaboration to leverage resource integration and industrial synergies. The HJT sector’s sustained growth demands a trinity of technology, capital, and scenario.

Xing Zhou, Vice President of Huasun, discussed the company’s global market expansion. “Huasun has launched more than 20 vertical installation pilot projects in China, while the Middle East and Southeast Asia—regions with high solar irradiance—will be key overseas markets,” Xing said. He highlighted that HJT modules in the Mohe project achieved a measured power gain of 8.77%, positioning real-world performance data as a key asset in market expansion. Comparatively, focusing solely on front-side efficiency at the expense of overall power generation capability is no longer sufficient in a market where clean energy pricing is becoming increasingly competitive. In response to the industry’s price competition chaos, Xing said, “Vicious competition will only overdraw the industry’s future. Technology premium and reasonable pricing are the sustainable path.”

The End

The leap from 740W+ to 760W+ is more than just a numerical milestone—it marks China’s transition from “scale leadership” to “value leadership” in the PV industry. It reflects the club members’ commitment to advancing new productivity through HJT technology, optimizing manufacturing simplicity and cost efficiency to deliver the highest conversion efficiency and overall power generation capability.

“The industry urgently needs an evaluation system that truly reflects comprehensive power generation capacity, incorporating real-world parameters such as bifacial gain and degradation rates,” said Xu. “A well-ordered competitive market should return to its fundamentals, empowering customers with choice and allowing application to drive demand to shape the industry. It can enable the industry to develop sustainably and healthily.”

With the official launch of the HJT Leadership Initiative, this conference has sent a clear signal. HJT is fortifying the strategic moat for national energy security, anchored in its triple strengths: high-efficiency operation, low-carbon footprint, and multi-scenario adaptability. With patent-unconstrained proprietary architecture and full lifecycle performance superiority, HJT constructs a moat of national energy security.

As TOPCon disrupts the PERC era with cost-performance advantages, and HJT unlocks global markets with superior power generation and patent security, China’s PV industry has proven that only technologies validated by real-world performance can become true engines of industrial transformation. The mission of the 760W+ Club is to harness the power of ecosystem collaboration, ensuring that every watt of electricity becomes a testament to the energy revolution.